Basic Information

The Lasape Chemical Markers

The development of chemical markers by Lasape through the process of production and synthesis dyes fluorescent non-commercial that are capable of emitting different colors in the visible when illuminated by ultraviolet light in the presence of different solvent(positive solvatochromism). For example, with the addition of hexane solvent will obtain a green color on the residue after solvent evaporation, followed by addition of dichloromethane can observe the red color, etc.

Chemical markers have a wide range of applications which are:

Chemical markers in HDPE (High Density Polyethylene)

In paper money.

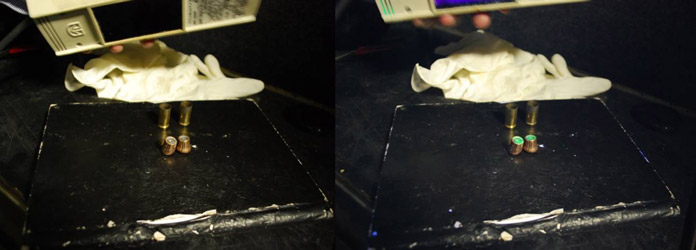

Marking of ammunition

After firing a firearm projectiles deform or fragment hampering the ballistic analysis and removal (if any victim).The marking of ammunition allows differentiate accurately a suicide, an accident, or murder, besides marking victims involved with shooting short or long distance, increasing the chances of solving the problem of "stray bullets".

The visible observation is performed by irradiating with a UV fluorescent dye present in the marked artefact which allows the display of different colors by addition of different organic solvents, a mixture of the associated ("bouquet") non-fluorescent substances.Using modern instrumental techniques will be possible to identify each unit of the security and defense forces, reaching levels of detailed identifications including ordinary citizens, holders of weapon carrying permit or not and illegal users of firearms.

The use of marked ammunition will:

- Identify the location where the shot was made;

- Identify the shooter as well as those positioned nearby;

- Check the points where the bullet impacted, beyond obstacles where transfixaram; beyond the end point of rest;

- Combat action fraudsters, able to build ammunition with commercially available fluorescent dyes therefore able to be used in the marking of powders and projectiles;

- Facilitate the work of internal affairs and "blitzes" in the seizure of illegal ammunition in firearms, considering that the use of inorganic fluorescent substances enables score the cover and the cover of the projectile. This technology is unique in the world described that identifies a carrier of ammunition marked without the need to make a shot. This is possible because in the process of manufacturing the kit alloy modified Tonbak is melted above 1800 ° C, then added with inorganic fluorescent substances, which will mark the case and wrap the projectile of lead on the firearm.

See Technological Consultancy for more information.